Mad about Science: Underwater tunnels

By Brenden Bobby

Reader Columnist

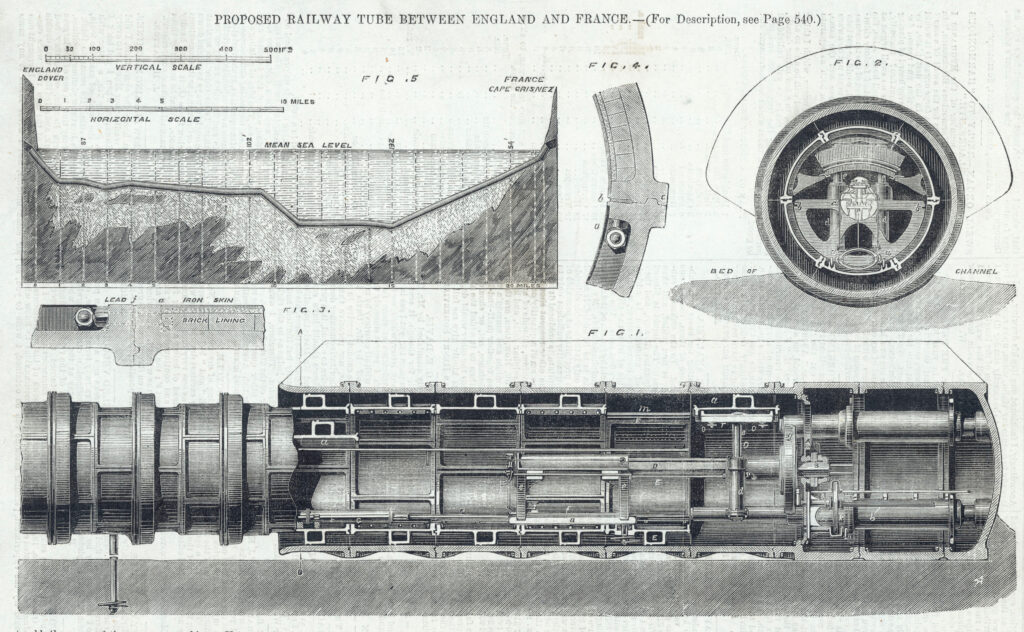

We’ve explored the exciting world of boring machines a few times over the past few months, most recently talking about the impressive tunnel systems drilled through the Swiss Alps. What happens when we want to drill under a body of water to connect two landmasses?

There are a lot of factors to consider when drilling under a body of water. The first consideration is the grade of the tunnel. A steep grade will take more energy for vehicles to ascend or create hazardous conditions during descent. Mountain passes are treacherous for large vehicles, which is why you see so many runaway truck ramps built throughout the western United States. Unlike a mountain pass, where engineers are adapting to existing topography, there’s a great deal of control involved with preparing the grade of an underwater tunnel.

Another consideration is what exactly crews will be drilling through. Water naturally seeks to fill voids in its endless pursuit to find the path of least resistance downward while also permeating everything. Scooping wet silt will make more wet silt slough into the void, which isn’t conducive to a boring machine.

A boring machine needs densely compacted soils or rock to function optimally, otherwise it’s basically just trying to grind its way through a giant bowl of wet oatmeal.

Pressure is always a consideration for boring a tunnel. Engineers must account for the weight of rock and water on top of the tunnel and need to be aware of how it may shift over the years due to earthquakes, settling or even currents generated by ships. Imagine setting a cinderblock on top of a shoebox — you’re going to have to reinforce the heck out of that box if you don’t want the rock to crush your retro Jordans.

All of these considerations lead one to wonder, why build a tunnel at all? Why not just build a bridge?

This is often the first question asked by politicians seeking to connect two landmasses. In some cases, a bridge may be impractical for reasons beyond engineering, such as overshadowing a historic landmark or hindering ships moving through a port. Building a tunnel solves these issues.

One of the most interesting ways to build a tunnel is also the most impractical. Instead of boring through unstable silty substrate, engineers have occasionally opted to prefabricate huge concrete sections of a tunnel and drop them into the water to link together like giant LEGOs. This means they only generally need to do minimal boring on either side of the tunnel, if at all.

This is a technique called immersed tube tunneling.

In the most basic terms, huge concrete sections of tunnel — up to 650 feet long — are built in drydock and then attached to tugboats and floated to the construction site. They’re lined up and dropped into place then pressed together. Crews do this until both landmasses are connected, and bada bing, bada boom, you have an underwater tunnel.

“Wait a minute, Brenden, how are you going to float a concrete tunnel the size of a city block?”

That’s likely the simplest part of this entire process. By placing two watertight bulkheads on either side, this massive structure is going to float on its own thanks to the huge amount of air trapped inside. Placing the segment in its final resting place and sinking an object that’s designed to function like a boat initially is a bit more complicated.

It’s handed over to something called a lay barge, which is equipped with cranes and heavy machinery that work to line it up with the existing sections of the tunnel. To sink the tunnel segment, water tanks attached to the tunnel are filled to reduce its buoyancy and bring it down into the trench where it will rest. Lining up the tunnel segments is the most critical part; and, while you might think this would take a tremendous amount of time, it needs to be completed quickly to account for things like tides and ship traffic.

Rubber gaskets are built into the tunnel segments that will squish and deform when the segments are pulled together to create a watertight seal. In some cases, the tunnel segments are fitted with hydraulic jacks that pull them together, while others may use something akin to a train car coupler. In other cases, the lay barge will drag it into place and press the two pieces together. The final step to sealing is draining the bulkheads, which creates a pressure difference between the two sides of the tunnel, pulling the existing pieces tightly together and protecting the structure from changes in water pressure or currents.

After they’re connected, crews will backfill from the surface to bury the tunnel as an extra layer of protection.

Once both sides are connected, the tunnel isn’t quite ready to be opened to the public. It’s basically just a big concrete tube and still needs to have roads laid, lights and electrical added and ventilation installed.

Immersed tube tunnels can unfortunately be extremely damaging to wildlife and waterways, especially when compared to traditionally bored tunnels. Dredging and moving huge amounts of sediment can deal a huge blow to aquatic life and ecosystems, or even pull up buried contaminants that had been illegally dumped. Because of this, immersed tube tunnels are not the default option for tunnel creation, even if it seems like the most cost-effective and practical method available — though it rarely is. There are fewer than 200 of these structures around the world, compared to at least 5 million bridges that currently stand.

Stay curious, 7B.

Coming up this week! Don’t miss Live Music, the Summer Sampler, the Art Party, Monarch Grind, the Sandpoint Renaissance Faire, and more! See the full list of events in the

Coming up this week! Don’t miss Live Music, the Summer Sampler, the Art Party, Monarch Grind, the Sandpoint Renaissance Faire, and more! See the full list of events in the